Business

Laser Annealing

Laser Annealing for Semiconductor

Laser Annealing for Semiconductor

- VisAA offers optimal laser annealing processes that are required where conventional annealing tool is unable to fulfill the performance.

- Multi-wavelength system provides precise control of annealing depth and continuous wave laser irradiation performs gentle annealing

treatment without affecting neighboring structure.

-

VisAA (Visible-laser Activation Anneal) / VisMA (Visible-laser Melting Anneal)

Multi Function Wafer Annealing Machine

- Fine activation process: Diffusion-free, excellent Rs uniformity

- Anneal depth control via multiple wavelength laser

- Single or multiple wavelengths simultaneous irradiation on demand

- Smooth roughness after annealing

- Multi-wavelength optimized optics, precision stage and small foot print

-

Application

- Wafer Ion Implant Activation Process

- Void Remover to DRAM Deep Trench Structure Reflow Process

Main Specifications

| Item | Specification | |

|---|---|---|

| System | Semiconductor wafer annealing system by laser beam irradiation | |

| System configuration |

1) Laser & Optics system 2) Stage 3) Heating chuck system 4) Alignment & Monitoring system 5) Operating software |

|

| System Size |

Approximated size: 2,440(W) x 1,920(D) x ≤ 2500(H) Approximated weight: 4ton |

|

| Available workpiece |

Material : 200mm wafer Thickness : <1mm |

|

| Installation Environment | Temp/Humidity |

Temperature control ≤ ±2℃ Humidity control 55% ± 10% |

| Clean room | Class 1000 | |

| Vibration | VC-C | |

| Laser | R-G-B Laser | |

| Optics |

Beam mode : Rectangular flat-top Beam size : >160x100µm² / >800x500µm² Power density : >2x10⁵W/cm² (RGB each) / >8x10³W/cm² (RGB each) |

|

| Heating chuck |

Heater Power : 208V, 1,770W Available Temp. : 380 °C (Max : 400 °C) |

|

| Stage | X, Y, Z and θ axis | |

| Accuracy | ≤ ±1μm | |

| Software function |

Recipe editor Wafer alignment Leveled user access control Data logging |

|

| Alignment | Lens magnification | 2X, 10X |

Process performance

-

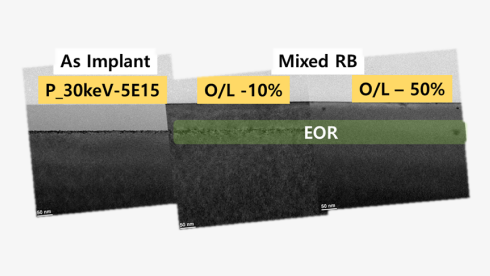

Dopant Activation Process

Dopant Activation Process

-

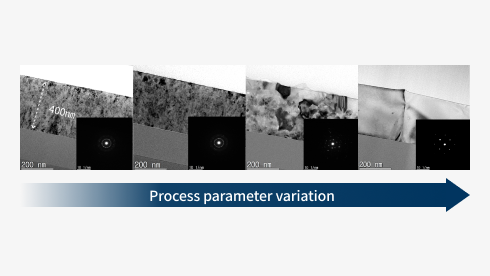

Void Melting Process

Void Melting Process