Business

Precision Laser Processing

FMM Manufacturing / Cutting

Laser Patterning, Laser Repair for fine Metal Mask

With ultra short pulse laser for cold-cut process, direct patterning or repair process on the material can be achieved without any burr occurred.

-

FI 1000 / CI 1000

All in one FMM stick Fabricate Machining

- Laser: Cold ablation by ultrashort pulse duration

- Mask projection: Finely controlled shaping

- Linear stage motion: Seamless processing

- Unique process: Exclude harmful thermal effect

-

Application

- OLED Organic Evaporation Process

-

FI 1000

FI 1000

-

CI 1000

CI 1000

Main Specifications

| Item | Specification | |

|---|---|---|

| System configuration |

1) Laser and optics unit 2) Stage and invar sheet chucking unit(ESC) 3) Alignment and measurement unit(Vision) 4) Electric and control unit(OP PC) |

|

| System Size | 3000*4000*2200(W*L*H) ã2 | |

| Available workpiece | Material | Invar film 10 ~ 300ã |

| Process target |

1) FMM pattern 2) Dummy(half etching, through hole, slit) / cutting |

|

| Installation environment | Temp/Humidity | Temperature control †±1° Humidity control †±5% |

| Clean room | Class 1000 | |

| Vibration | VC-C | |

| Laser | Femtosecond laser | |

| Optics | Beam shaping and projection optics | |

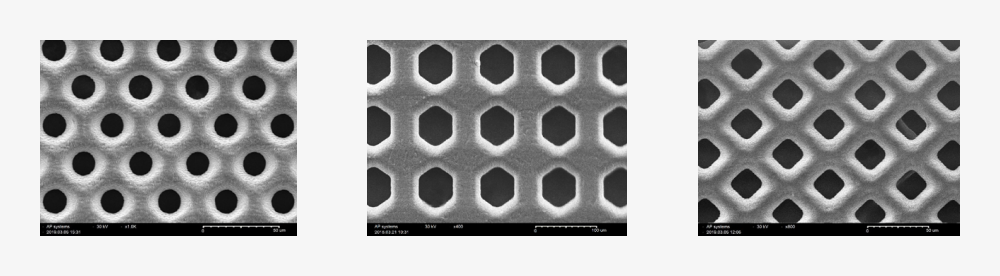

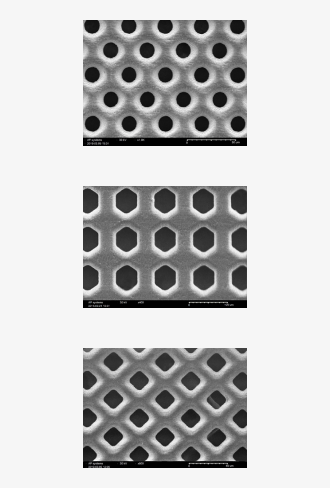

| FMM process | Process shape | Circle, square and polygon shape |

| Min. hole size | Ί10ÎŒm for circle, â¡10ÎŒm for square | |

| Size accuracy(3Ï) | †±1.0ÎŒm | |

| Positioning accuracy(3Ï) | †±1.0ÎŒm | |

| Stage | X, Y, Z and Ξ axis | |

| Accuracy | †±1Όm | |

| Work handling and chucking | Manual loading & unloading | |

| Substrate chuck | †±1Όm | |

| Flatness | †20Όm | |

| Alignment | Lens magnification | 10X, 20X,. 50X(optional) |

| Alignment accuracy | †±1Όm | |

Process performance

FMM Repair

CIR 1000

-

Automatic & Multi Function FMM Repair Machine

- Various type and shape of Defect Repair Support

- Defect CD and position accuracy Control in 1ÎŒm

- Holes Taper Angle Control Available

- Full Automatic FMM Repair Process

-

Application

- Defect removal after FMM Processing

Main Specifications

| Item | Specification | |

|---|---|---|

| System configuration |

1) Laser and optics unit 2) Stage and invar sheet chucking unit (ESC) 3) Alignment and measurement unit (Vision) 4) Electric and control unit (Operation PC) |

|

| System Size | Main Body | 3700 x 3500 x 2800(mm) |

| Loader | 2400 x 2200 x 2800(mm) | |

| Available workpiece | Material | Invar film 10 ~ 300µm |

| Process target | 1) FMM Repair 2) FMM Shape cutting |

|

| Laser | Femtosecond laser | |

| FMM process | Process shape | Circle, Square, Diamond, Hexagon, Polygon Shape |

| Min. hole size | Ί10ÎŒm for circle, â¡10ÎŒm for square | |

| Size accuracy(3Ï) | †±1.0ÎŒm | |

| Positioning accuracy(3Ï) | †±1.0ÎŒm | |

| Stage | X, Y, Z and Ξ axis | |

| Accuracy | †±1Όm | |

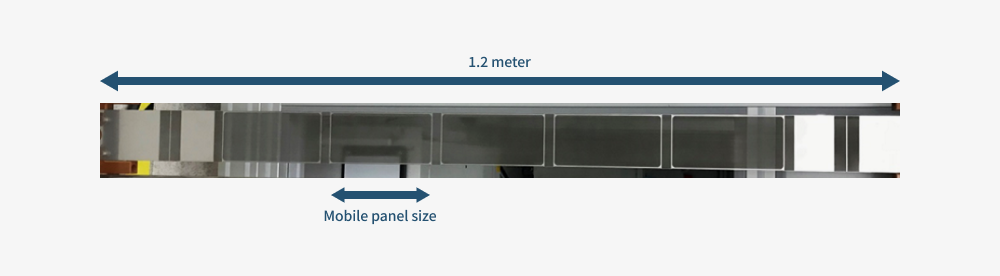

| Work handling and chucking | Automatic loading & unloading †300mm (width) | |

| Substrate chuck | ESC(Electro-Static Chuck) | |

| Flatness | †20Όm | |

Process performance

-

Auto Repair Process Video

-

Automatic FMM loader

Automatic FMM loader